As the worldwide interest for seaward energy, transportation frameworks, and manageable marine improvement keeps on developing, these mechanical headways are making ready for another period in marine designing.

Throughout the course of recent many years, huge advances in marine development innovation have reshaped how designers approach submerged foundation, bringing about more productive, manageable, and tough designs.

Marine development has for some time been a field that requests advancement, versatility, and accuracy because of the cruel and flighty nature of the sea climate.

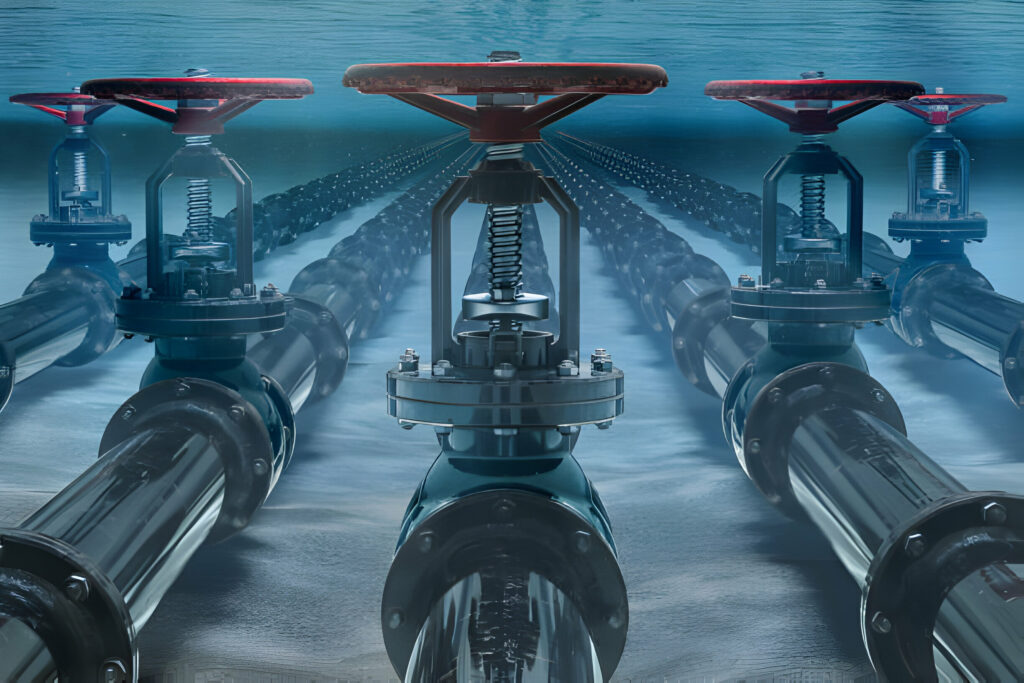

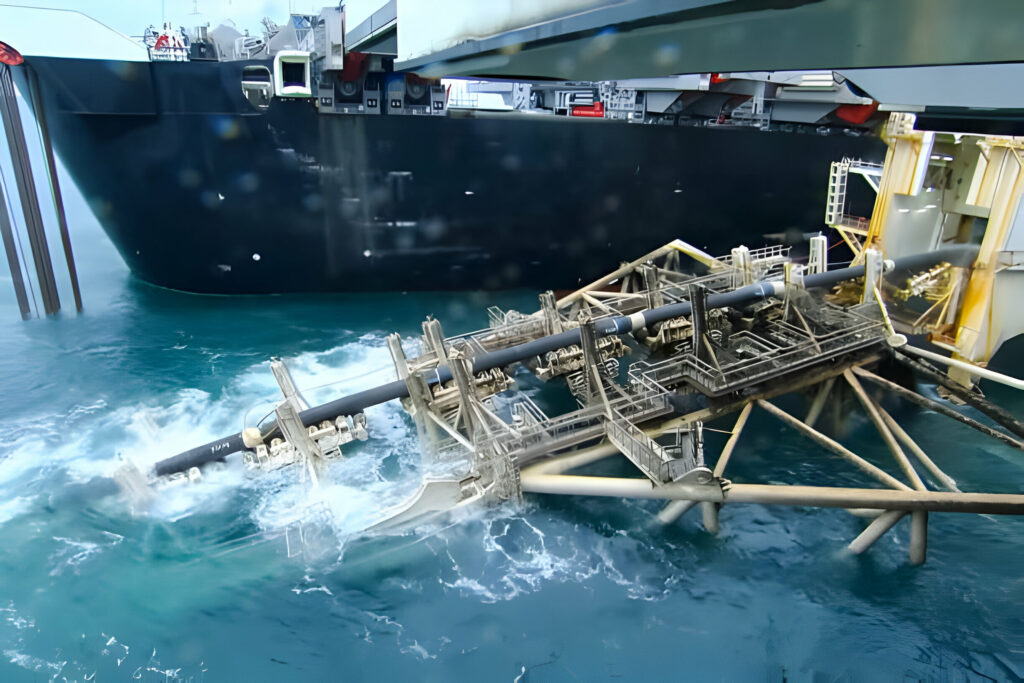

In any case, as seaward penetrating, subsea pipelines, and other marine framework turned out to be more far reaching, the requirement for additional refined devices and hardware became clear.

These automated frameworks took into consideration more profound and more exact tasks, diminishing the dangers related with human presence submerged and opening up additional opportunities for subsea development.

Engineers are currently ready to plan and build more complicated and strong designs while limiting ecological effect and diminishing development time.

During the 1950s and 1960s, forward leaps, for example, the advancement of the plunging chime and later immersion jumping permitted laborers to stay at more noteworthy profundities for longer periods, empowering the development of submerged stages and pipelines.

Today, marine development consolidates the most recent advances in mechanical technology, material science, PC displaying, and manageability practices to make another rush of seaward foundation.

All things considered, marine development included a lot of difficult work and simple instruments, depending on human jumpers to perform submerged undertakings like welding, review, and upkeep.

Perhaps of the main development in marine development innovation is the turn of events and arrangement of mechanical technology and mechanization frameworks. Remotely worked vehicles (ROVs) and independent submerged vehicles (AUVs) are currently fundamental apparatuses in submerged development, giving both the flexibility and wellbeing expected for these difficult conditions.

These vehicles are outfitted with superior quality cameras, sonar, and automated arms that can perform complicated errands like welding, cutting, and gathering subsea foundation. Some ROVs are even fit for dealing with complex establishments, for example, laying subsea pipelines or associating submerged links, undertakings that would somehow require human jumpers working in unsafe circumstances

The test of working underneath the ocean, whether for oil rigs, subsea pipelines, or fake islands, requires state of the art innovation, specific materials, and a multifaceted comprehension of marine circumstances.